Glow in the Dark Paint

Our phosphorescent paint glows naturally in the dark and illuminates under UV black lights.

Techno Glow's glow-in-the-dark paint is a premium indoor and outdoor acrylic paint. It is made from the highest quality materials for the ultimate glow suited for all weather conditions. A multi-purpose photoluminescent paint ideal for walls, aluminum, canvas, concrete, paper, fabric, rocks, steel, or wood. Available in natural and bright fluorescent colors.

Charge from any light source, such as sunlight, UV black lights, or indoor lighting. A fluid ounce of paint covers about 3 square feet of the primed surface. Apply 2 to 5 layers for a more even and streak-free glow. Application instructions and other information are available at the end of this page.

-

Indoor & Outdoor

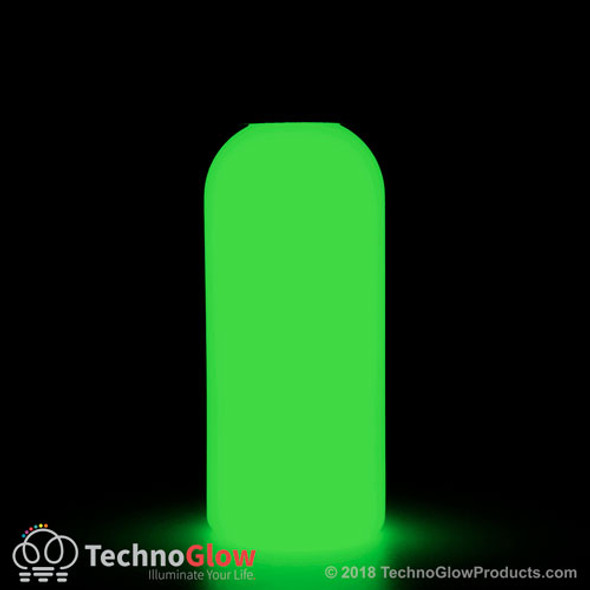

Green Glow in the Dark Paint - Brightest Glow

TechnoGlow

$9.00 - $320.00Brightest Glow in the Dark Paint Looking for the brightest glow-in-the-dark paint? Look no further! Our green glow-in-the-dark paint is the top choice for many, thanks to its remarkable luminosity. Green is the brightest and longest-lasting of all...TOB-GRN$9.00 - $320.00 -

Indoor & Outdoor

Aqua Glow in the Dark Paint - #2 Choice Glow Paint

TechnoGlow

$9.00 - $320.00Aqua Glow in the Dark Paint Aqua glow in the dark paint is an off-white color in normal lighting and glows with a beautiful aqua luminescence reminiscent of a tropical ocean surf. It has quickly become one of the most highly coveted phosphorescent paint...TOB-AQU$9.00 - $320.00 -

Indoor & Outdoor

Blue Glow in the Dark Paint - #3 Choice Glow Paint

TechnoGlow

$9.00 - $320.00Blue Glow in the Dark Paint Indulge in the soothing ambiance of blue glow in the dark paint! This paint is a simple white color that may appear somewhat transparent in daylight with just a few layers. In the dark, it radiates a beautiful, vibrant...TOB-BLU$9.00 - $320.00 -

On Sale

41-Piece Deluxe Glow in the Dark Paint Set

TechnoGlow

Now: $84.99Was: $140.00Glow in the Dark Paint Kit This TechnoGlow premium glow in the dark acrylic paint kit is a complete set of 9 glow paints, brushes, and applicators. This unique package includes everything one needs to brighten their lives and discover the inner...PST-MIX-2015Now: $84.99Was: $140.00 -

White Glow in the Dark & UV Paint

TechnoGlow

$15.00 - $485.00White Glow in the Dark Paint This white glow in the dark paint appears transparent to a white color in daytime and glows white in the dark. It has been used by many of our customers for adding accents and highlights in paintings or text on signs for...TOB-WHT$15.00 - $485.00 -

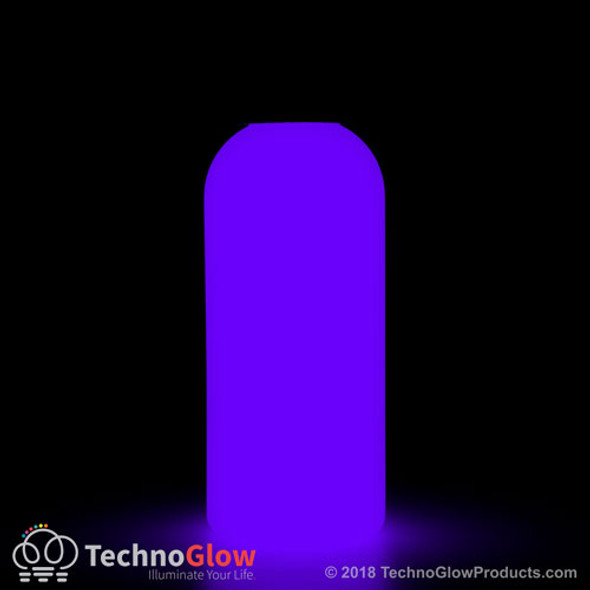

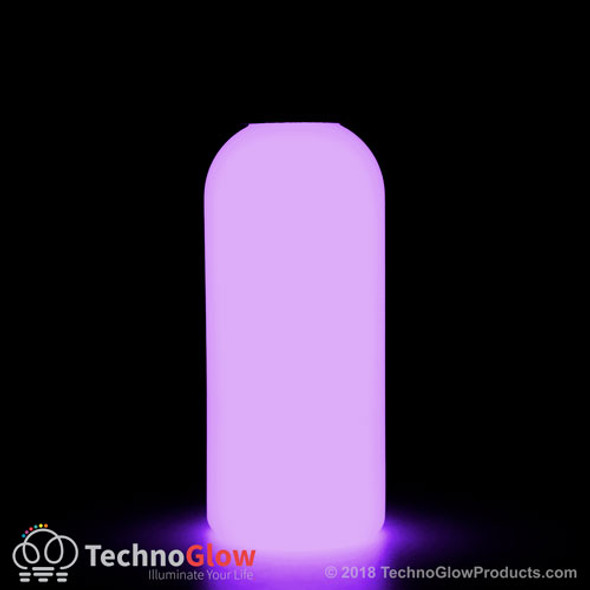

Purple Glow in the Dark & UV Paint

TechnoGlow

$9.00 - $320.00Purple Glow in the Dark Paint Purple glow paint that is white in the day and a magical lavender glow at night. This paint takes longer to charge then other colors. Charges faster by sunlight or with a black light. Charge with any natural or artificial...TOB-PPE$9.00 - $320.00 -

Pineapple Yellow Glow in the Dark & UV Paint

TechnoGlow

$9.00 - $320.00Yellow Glow in the Dark Paint Pineapple Yellow is a bright yellow daytime color with a true yellow night time glow. This paint will glow for over 5 hours. It is also an ultraviolet paint that illuminates under a black light, day or night. Charge the...TOB-PYL$9.00 - $320.00 -

Cotton Candy Glow in the Dark & UV Paint

TechnoGlow

$9.00 - $320.00Cotton Candy Glow in the Dark Paint Cotton Candy is a vibrant pink paint that glows a soft pink with hints of blue and purple hues. This paint was used to create stunning effects at Disney's new theme park "World of Avatar - Pandora." It's an excellent...TOB-LPK$9.00 - $320.00 -

Orange to Gold Glow in the Dark & UV Paint

TechnoGlow

$9.00 - $320.00Orange to Gold Glow Paint This unique glow paint features an orange color during the day and emits a gold glow at night, lasting over 6 hours. It's perfect for situations where you want a colorful glow with the flip of a switch or a bright gold...TOB-ORE$9.00 - $320.00 -

Pink to Rust Glow in the Dark & UV Paint

TechnoGlow

$9.00 - $320.00Pink to Rust Glow in the Dark Paint This unique glow paint has a pink color during the day and a rusty gold glow at night. Pink to Rust will glow for over 6 hours. Ideal for scenarios to see a colorful glow with the flip of a switch or to illuminate a...TOB-PNK$9.00 - $320.00 -

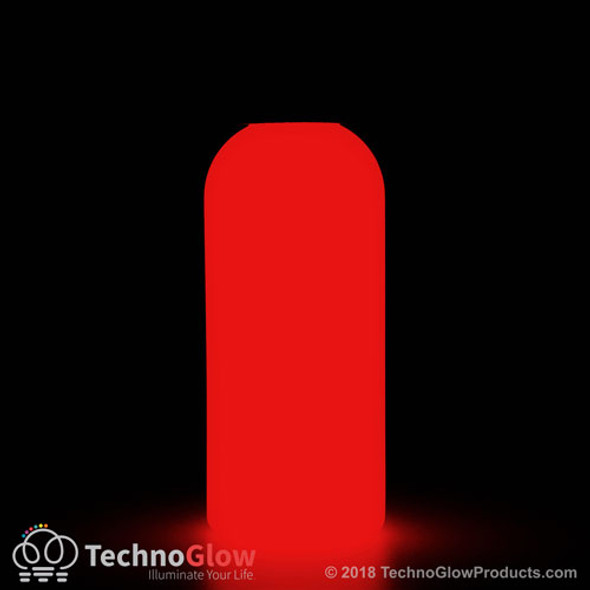

Invisible Red Glow in the Dark & UV Paint

TechnoGlow

$15.00 - $485.00Invisible Red Glow in the Dark UV Paint Invisible red glow paint can be charged with any natural or artificial light. Due to its short glow time, red is better suited as a UV paint rather than a glow paint, with a natural glow lasting under 30 minutes...TOB-IRED$15.00 - $485.00 -

Neon Yellow Glow in the Dark & UV Paint

TechnoGlow

$9.00 - $320.00Neon Yellow Glow in the Dark Paint A neon yellow color during the day with a green glow in the dark. Ideal for scenarios to see a colorful glow with the flip of a switch or to illuminate a bright green under a UV blacklight. Can be charged by any source...TOB-YLW$9.00 - $320.00 -

Fluorescent Green Glow in the Dark & UV Paint

TechnoGlow

$9.00 - $320.00Fluorescent Green Glow in the Dark UV Paint A fluorescent green color during the day and a bright green glow at night. This daytime green paint will glow for over 6 hours. Ideal for scenarios to see a colorful glow with the flip of a switch or to...TOB-LGRN$9.00 - $320.00 -

Glow Paint Performance Kit + UV Light

TechnoGlow

$25.00 - $95.00Multi-Color Outdoor Glow in the Dark Paint Kit The performance sample pack features our three most popular glow in the dark paint set colors that have all earned an average five star rating. These glow in the dark paints are tried and proven to be the...TOB-KIT-GPP$25.00 - $95.00 -

6 Sizes

Transparent Acrylic Paint for Glow Powder & Fluorescent Pigment

TechnoGlow

$5.95 - $84.95Clear Acrylic Paint Transparent acrylic paint for mixing with glow in the dark powder, fluorescent UV powder, or other color changing pigments. Does NOT glow in the dark on its own. Glow powder must be added for the paint to glow. A durable and...TOB-CLR$5.95 - $84.95

Featured Video

Glow Paint & UV Laser Lights

Our paint glows naturally in the dark after any light exposure and reflects under UV lights. This video demonstrates how a UV laser pen can instantly charge glow paint for a fun mural exhibit. The best wavelength for UV light is between 365-405nm

Features

- Multi-Purpose Acrylic Glow Paint

- Durable Quality for Industrial Use

- Brightest Green, Aqua, and Blue for Outdoor Use

- Largest Selection of Glow Colors

- Glows Naturally in the Dark and UV Black Light Reactive

- Brush or Roller Applications

- Visible and Invisible Glow in the Dark Colors

- Easy Storage and Cleanup with Hot, Soapy Water

- Made from Techno Glow's Best Materials

- 1 Year Shelf Life

Applications

- Commercial and Industrial Use

- Create the Brightest Star Mural Ceilings and Walls

- Paint Washable Glow in the Dark Clothing

- Acrylic Pouring for Canvas or Art Paintings

- Theme Parks, Night Clubs or Museum Effects

- Signage, Greeting Cards and Much More

- Glow in the Dark Rocks for Landscaping

- Photoluminescent Safety Signage

- Indoor Outdoor Walls

Instructions

Obtain and apply a primer appropriate to your application. A white primer will facilitate the highest glow by reflecting the glowing light, while a dark primer will reduce or absorb the luminosity. A primer might not be needed if you have a cured, dry, light-colored, clean surface.

Paint can be thinned with water or an acrylic extender if needed. As with all other phosphorescent paint, you can apply up to 5 layers for the ultimate glow. The more layers you apply, the more solid and even the glow becomes. It dries to the touch in under 2 hours. A hairdryer can be used to dry the paint fast.

Clean spills and spatters, hands, and tools with soap and warm water. Keep the paint lid or cap closed at all times. Do not allow the paint to freeze. The shelf life is one year.

We have tested and compared our paint layer by layer with every other acrylic on the market, and we are proud to say that the Techno Glow paint is the brightest and most durable on the market.

Frequently Asked Questions

Does the paint dry clear?

The color of the paint may be more or less noticeable depending on the number of layers applied and the intensity of the glowing effect.

Glow paint is made with photoluminescent pigments, which are visible and opaque in daylight. Therefore the natural colors that are white or off-white in light can appear somewhat invisible when applying only one or two layers. Multiple layers must be applied to achieve a brighter, solid, streak-free glow. The more layers you use, the more opaque the paint will appear.

The fluorescent colors with a bright, vivid color in the daytime can also appear transparent depending on the number of layers.

Can I use the paint in a spray gun?

The Techno Glow acrylic paint is highly concentrated with glow powder additives and is too thick for use with spray painting or airbrushing as is. Mix about one fluid ounce of water or an acrylic flow-aid to every four fluid ounces of glow paint to achieve a more manageable flow with a high-pressure spray gun. Due to the larger glow particles being used, it is also essential to use a nozzle that is 1.0 mm or larger.

For airbrushing, mixing the glow-in-the-dark powder with a clear or transparent medium is best to create your glow paint. Nozzle sizes of 0.5 mm or larger are required for airbrushing with 35 microns or larger pigments.